PVC Casing

Steel casing

Fiberglass casing

Completion Method

Open Hole Completion

Packer Completion

Gravel Packing

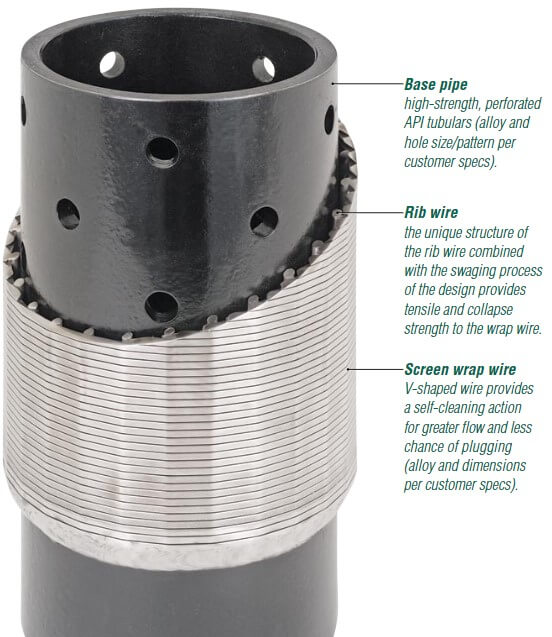

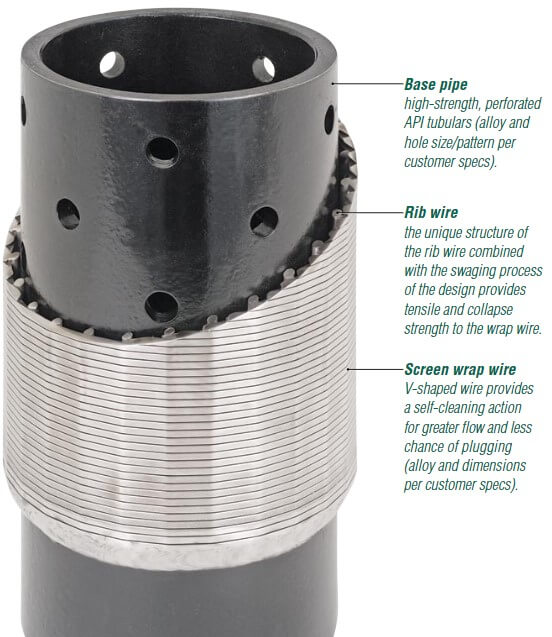

Type of Screen

Whether you're looking to initiate a new project or seeking maintenance on an existing well, our experienced staff is ready to provide efficient and timely solutions. Don't hesitate to connect with us and discover how our expertise can benefit both your residential and commercial needs.

For over 40 years, Bee Cave Drilling has been at the forefront of the drilling industry, providing exceptional and reliable services. But don't just take our word for it! Here's what our incredible community of customers have to say about their experience with us.

With a proven track record, we have established a strong reputation across multiple platforms. Our commitment to delivering excellence is reflected in the high ratings we've received from our clients, both long-standing and new.